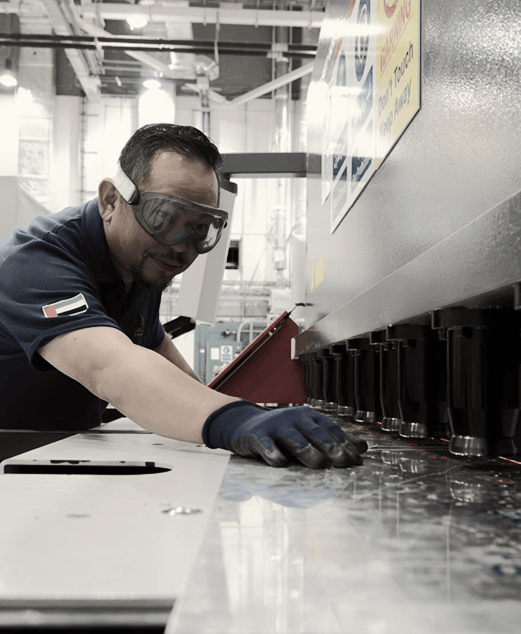

SUPPORT SHOPS

AMMROC’s comprehensive support shops are equipped with advanced tools and technologies to provide specialized maintenance, repair, and overhaul services for various aircraft components and systems.

Our facilities ensure precision, reliability, and efficiency across all operations.

MACHINE SHOP

SPECIAL PROCESS SHOP

NDT SHOP

STRUCTURE SHOP

COORDINATE MEASURING MACHINE (CMM)

CLEANING SHOP

CALIBRATION SHOP

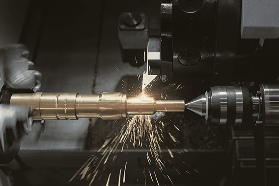

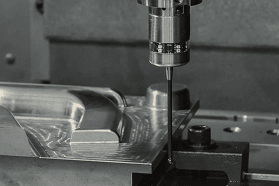

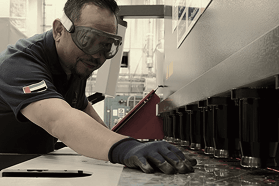

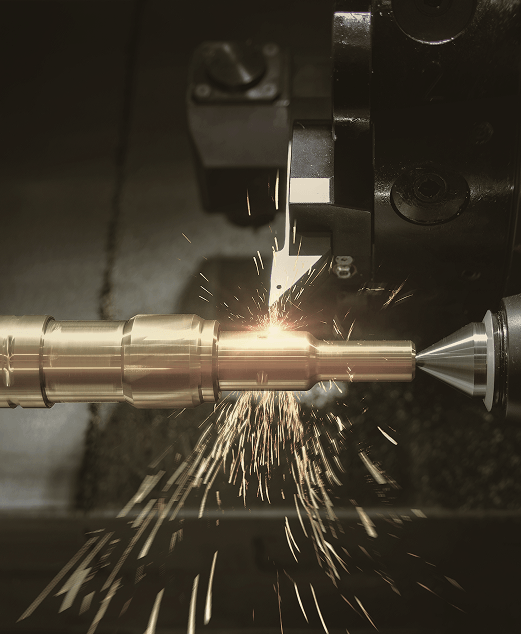

MACHINE SHOP

AMMROC’s Machine Shop is equipped with state-of-the-art CNC machines and conventional machining tools, providing precision manufacturing and repair services for complex aircraft components. Our capabilities ensure the highest standards of accuracy and quality.

From custom fabrication to intricate part restoration, our skilled machinists utilize advanced techniques to meet the stringent requirements of military and commercial aviation.

- Precision CNC machining (milling, turning, grinding)

- Conventional machining (lathe, drill press, surface grinding)

- Custom fabrication and part manufacturing

- Component repair and restoration

- Material testing and analysis

SPECIAL PROCESS SHOP

Our Special Process Shop offers a wide range of specialized treatments and coatings essential for enhancing the durability, performance, and corrosion resistance of aircraft components.

We adhere to strict industry standards and utilize advanced processes to ensure the integrity and longevity of critical parts.

- Non-destructive testing (NDT) (e.g., eddy current, ultrasonic, magnetic particle, liquid penetrant)

- Surface treatments (e.g., anodizing, passivation, chemical conversion coating)

- Thermal spray coatings (e.g., HVOF, plasma spray)

- Welding and brazing (e.g., TIG, MIG, electron beam)

- Heat treatment and metallurgical analysis

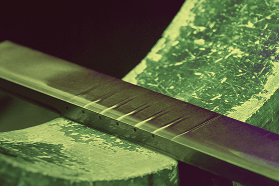

NDT SHOP

The NDT (Non-Destructive Testing) Shop provides critical inspection services to detect hidden flaws and defects in aircraft components without causing damage. Our certified technicians use advanced techniques to ensure structural integrity and safety.

We offer comprehensive NDT solutions to support maintenance, repair, and overhaul operations, ensuring compliance with international aviation standards.

- Eddy Current Testing (ECT)

- Ultrasonic Testing (UT)

- Magnetic Particle Testing (MPT)

- Liquid Penetrant Testing (LPT)

- Radiographic Testing (RT)

- Thermography

- Visual Inspection

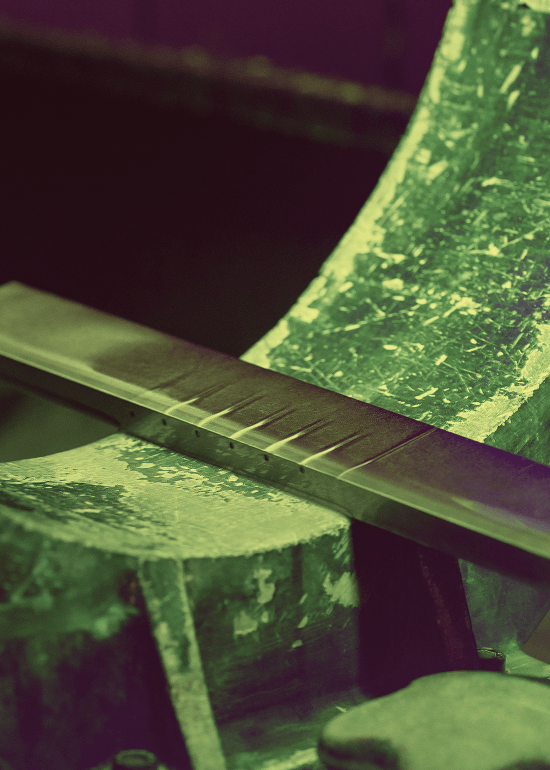

STRUCTURE SHOP

AMMROC’s Structure Shop specializes in the repair, modification, and fabrication of aircraft structural components. Our skilled technicians perform complex sheet metal work, composite repairs, and structural assembly to restore aircraft to airworthy condition.

We utilize advanced tools and techniques to address structural damage, ensuring the highest levels of safety and operational readiness.

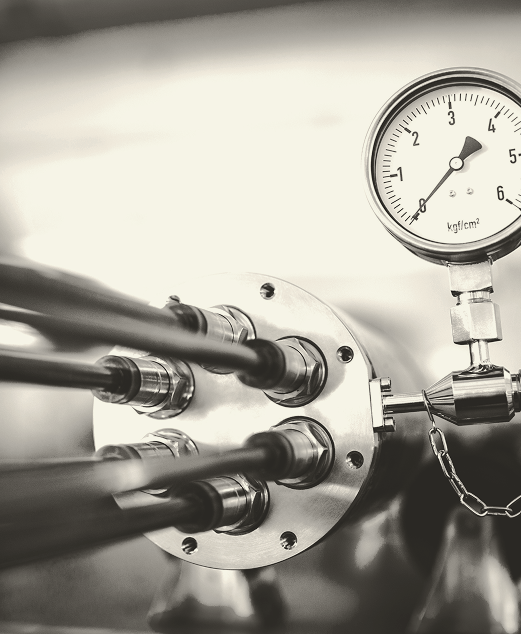

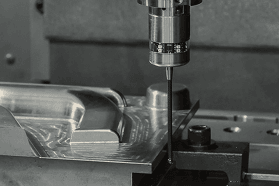

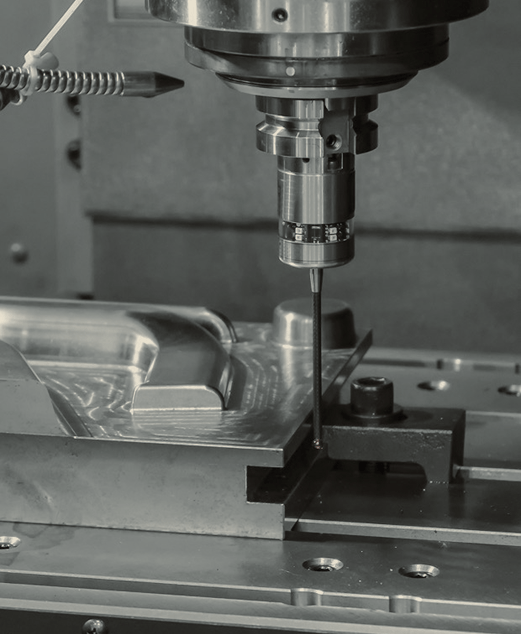

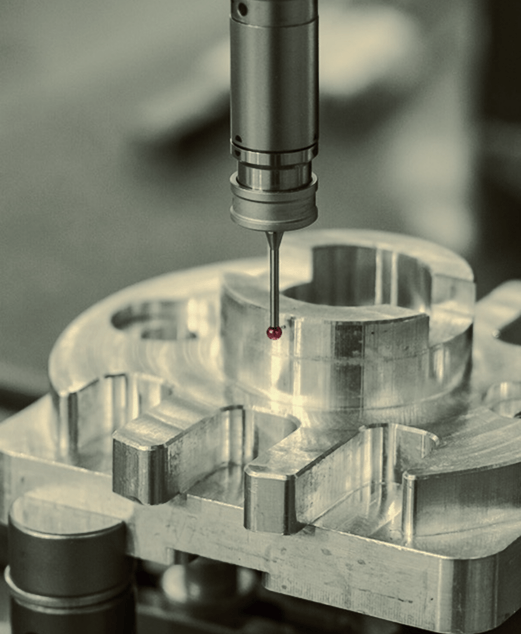

COORDINATE MEASURING MACHINE (CMM)

Our Coordinate Measuring Machine (CMM) facility provides ultra-precise dimensional inspection and verification of complex aircraft components. This advanced technology ensures that parts meet exact specifications and tolerances, critical for airworthiness.

The CMM plays a vital role in quality control, reverse engineering, and first article inspection, guaranteeing accuracy and reliability in all our MRO processes.

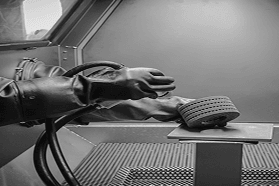

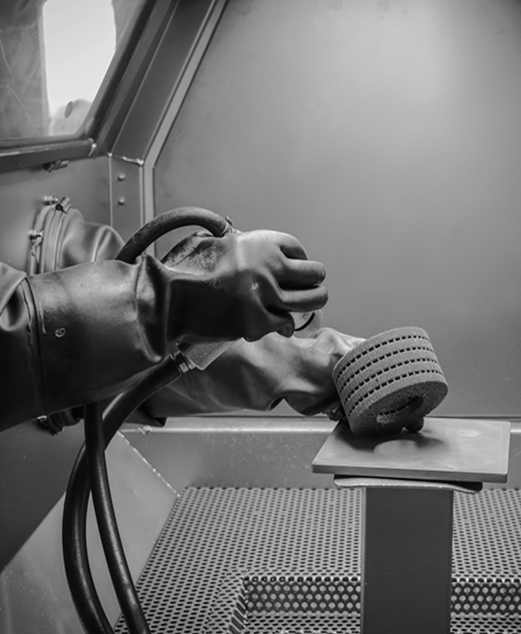

CLEANING SHOP

The Cleaning Shop provides specialized cleaning and degreasing services for aircraft components, removing contaminants, corrosion, and residues to prepare parts for inspection, repair, or assembly.

We employ environmentally friendly processes and advanced cleaning technologies to ensure thorough and effective cleaning without compromising material integrity.

- Ultrasonic cleaning

- Vapor degreasing

- Aqueous cleaning

- Grit blasting and shot peening

- Chemical stripping and passivation